Cylindrical Grinding Solutions

True custom solutions with workhead and tailstock combinations for parts of up to 6,000 lbs. Steady rests, workheads or center drive system can be mounted on individual manually operated or motor driven slides. Parts are clamped between centers hydraulically or by CNC force control.

OD contour grinding with or without oscillation is available. On board gage system mounted to the wheel head or machine table allow for high precision on board gaging of parts and process control.

Choose from multiple USACH models for application-specific requirements:

USACH CYLINDRICAL GRINDING SOLUTIONS

USACH 200 OD-L

Machine max length: 72” (2M)

USACH 300 OD-L

Machine max length: 118” (3M)

USACH 500 OD-L

Machine max length: 196” (5M)

Features:

- Infinitely adjustable hydrostatic wheel head

- Dual wheel head

- Rotary Standard or Radius dresser

- Dressing systems for Metal bond wheels

- Center Drive systems for part of up to 23” (600mm)

- Contact less wheel gaging

- Vision Systems

- In- and post process gage systems

- Custom steady systems with NC compensation and positioning capabilities

The Wheel Head:

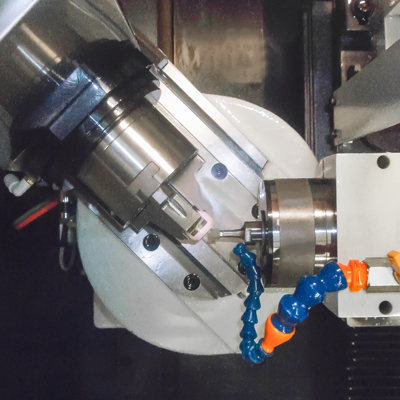

Several wheelhead configurations are available. A specialty of USACH is the combination of OD spindles with a swivel A-axis for flute grinding and OD grinding in one setup. For off center special features such as grooves or holes, spindles are mounted on a vertical axis. In addition, vertical and horizontal wheel changers are available, extending the machines flexibility.

Options:

- Software & Controls

- Workheads

- Center Drive

- Tailstocks

- Turrets

- Spindles

- Dressers

- B Axis and B1 Axis

- Auxiliary Axes

- Gaging and Pro

- Automation

- ID Option for OD Grinders

- FANUC 32 Series

- FANUC 0iF Plus

- Mitsubishi M70V

- Siemens 840 D

With its multi axis interpolation capabilities, USACH provides unmatched grinding solutions for sphere and mirror grinding. Complex alumina applications are processed with several spindles and a variety of tools that are automatically changed into the grinding spindles. Combining processes in one machine with multiple spindles provide customers with unique solutions that complete parts in one setup to the highest qualities and accuracies.